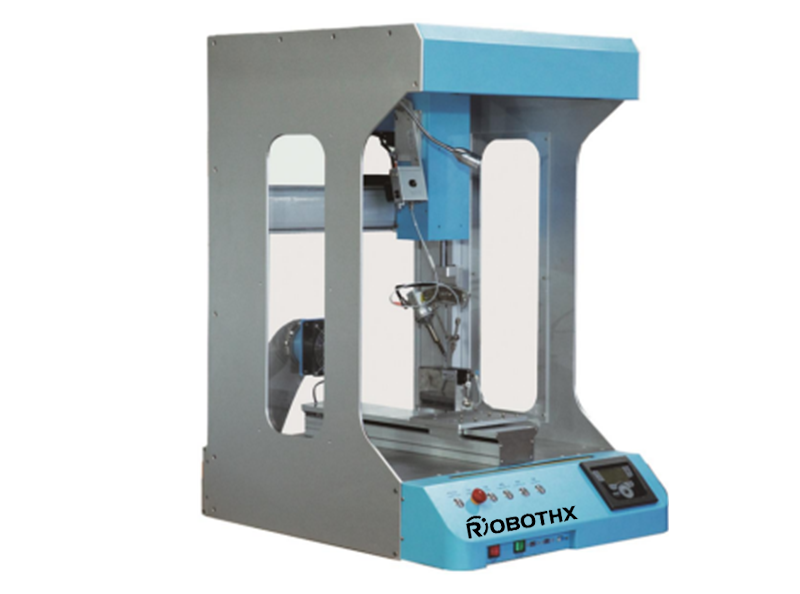

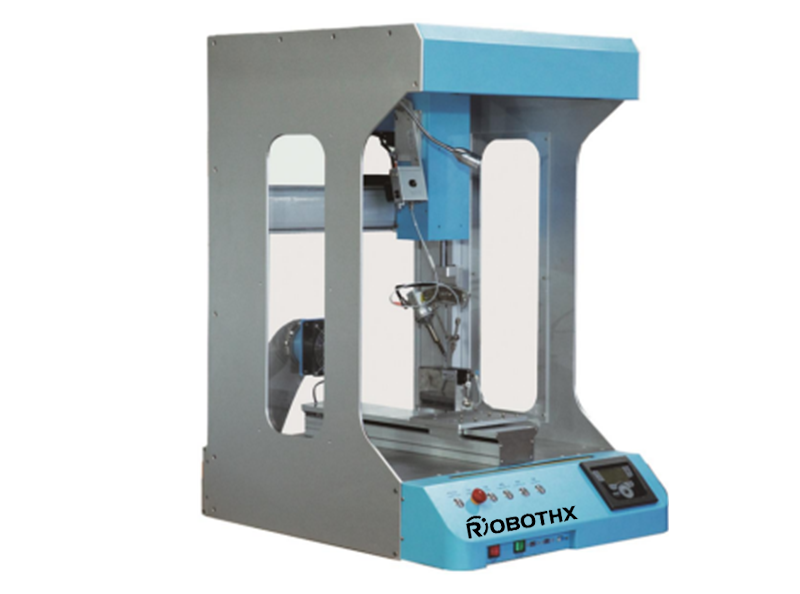

Vision soldering machine is a kind of high-end automation equipment, widely used in electronic manufacturing, automobile manufacturing, medical equipment and other fields. It has many advantages, can improve production efficiency, reduce labor cost, reduce defect rate and so on. Below we will introduce the functions and applications of the visual soldering machine in detail.

Functional characteristics

1. Automatic welding

The visual soldering machine has advanced automatic control system and precision machining device, which can realize high-precision automatic welding. Through the visual recognition technology and intelligent algorithm, the welding position can be quickly and accurately positioned, and the soldering operation can be carried out, which greatly improves the welding quality and efficiency.

2. Programmability

The visual soldering machine has a variety of built-in programs and parameter Settings to automate many different welding tasks. At the same time, users can also edit and optimize the program through the software to adapt to more complex welding needs.

3. Quality inspection

The visual soldering machine is equipped with high-precision sensors and inspection systems for real-time monitoring and inspection of welding quality. Through the feedback of the detection system, the welding parameters and process can be adjusted in time to avoid welding quality problems caused by human factors, thereby improving the efficiency and stability of the entire production line.

4. Reliability

Visual soldering machines use high-quality materials and components and are manufactured and assembled through a rigorous process. In the process of use, through regular maintenance and maintenance, the life of the equipment can be extended and the reliability and stability of the equipment can be improved.

Application field

Visual soldering machine is widely used in electronic manufacturing, automobile manufacturing, medical equipment and other fields. Specific application scenarios include:

1. PCB welding

In the production and assembly process of the PCB board, the circuit board needs to be welded several times. Using the visual soldering machine, you can achieve a fast and accurate welding process, and effectively control the solder amount and welding position to ensure that the solder joint quality meets the standard requirements.

2. Electronic component assembly

In the assembly process of electronic components, small components need to be accurately welded and connected. The use of visual soldering machine can achieve high-precision welding operation and avoid welding quality problems caused by human factors.

3. Automobile manufacturing

In automobile manufacturing, multiple welding operations are required for the body and parts. Using the visual soldering machine, you can achieve a fast and accurate welding process, and effectively control the welding position and solder amount, improve production efficiency and product quality.

Sum up

As a high-end automation equipment, visual soldering machine has a variety of functional characteristics and application scenarios, which can greatly improve production efficiency and product quality. In use, it is necessary to pay attention to the maintenance and maintenance of the equipment to extend the life of the equipment and improve the stability and reliability of the equipment. As a professional supplier of visual soldering machines, we will continue to innovate and optimize our product line to provide customers with the best quality products and services.