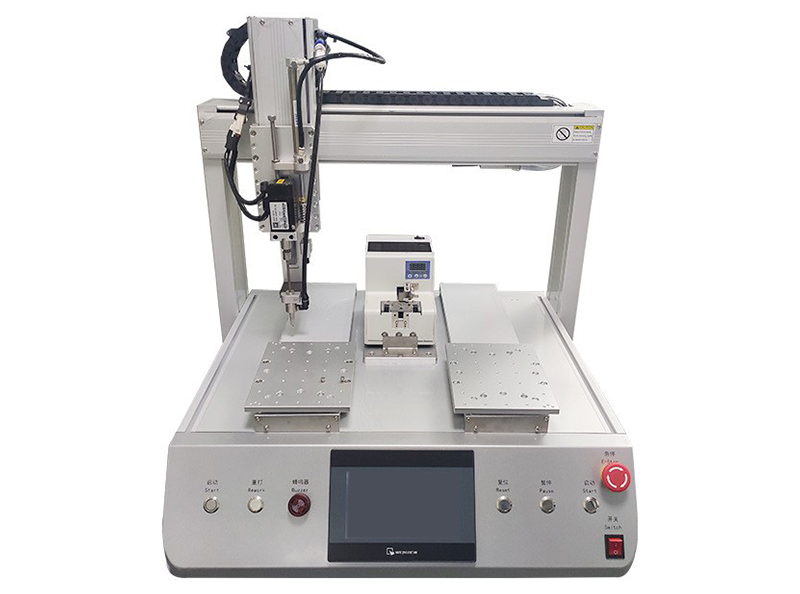

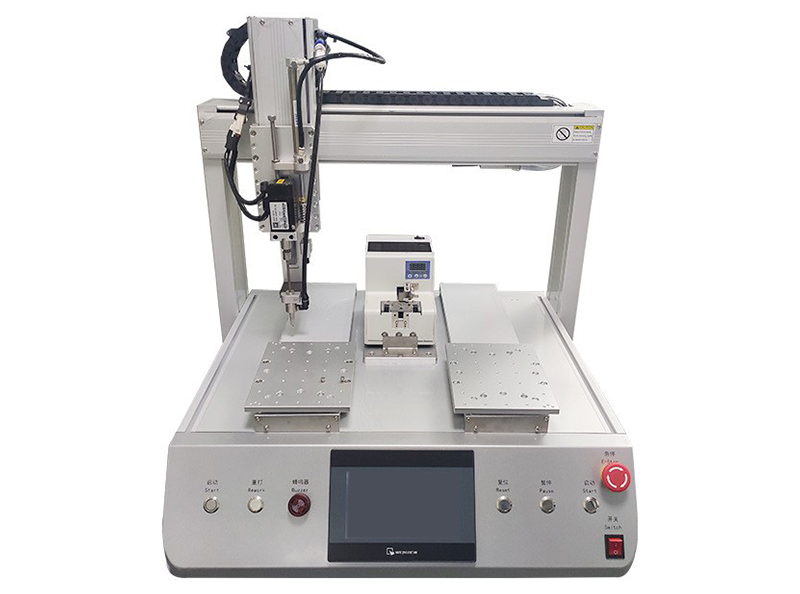

The computer version of the screw machine is an automatic assembly equipment, which can be used to speed up the batch assembly of screws and improve production efficiency. In the process of realizing automated assembly, there are several key steps to pay attention to:

Choose the right computer version of the screw machine

First of all, to choose a computer version of the screw machine suitable for production needs. Different types of computer version screw machines may have different functions and work ranges, which need to be selected according to actual production needs.

For example, in the case of a large number of small products, you can choose high-speed, multi-axis control, programmable function of the computer version of the screw machine; In the case of the need to assemble large products, you need to choose a larger size and high strength computer version of the screw machine.

Set the appropriate programs and parameters

Secondly, the appropriate procedures and parameters should be set to ensure that the computer version of the screw machine can complete the assembly task in accordance with the production requirements. The program setup should include information such as the type, size, and number of screws, as well as the order and steps of assembly.

At the same time, it is also necessary to take into account the material, hardness, surface treatment and other factors of the screw, and set the appropriate speed, torque and other parameters according to the actual situation to ensure the assembly quality and efficiency.

Ensure the stability of the feeding system

The feeding system is the key part of the normal operation of the computer version screw machine. It is necessary to ensure the stability and reliability of the feeding system to avoid production interruptions or product quality degradation due to insufficient supply or clogging.

For example, devices such as automatic feeders and vibrating plates can be used to ensure the continuous supply of screws, and abnormal conditions during feeding can be monitored through sensors and control systems.

Perform routine maintenance and maintenance

Finally, it is necessary to carry out routine maintenance and maintenance to extend the service life of the computer version screw machine and ensure its normal operation. Maintenance includes cleaning, calibration, replacement of consumables and other work, need to be carried out regularly, and record the corresponding maintenance records.

In addition, it is also necessary to regularly check and adjust the computer version of the screw machine to ensure that its functions and parameters are in the best state.

conclusion

The computer version screw machine is an important automatic assembly equipment, which can improve work efficiency and assembly accuracy in production. In the process of realizing automatic assembly, it is necessary to pay attention to selecting the appropriate computer version screw machine, setting the appropriate procedures and parameters, ensuring the stability of the feeding system, and carrying out routine maintenance and maintenance. Only when these aspects are achieved, can efficient production be achieved, while also extending the service life of the equipment and reducing maintenance costs.