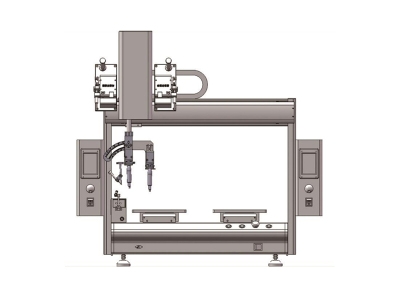

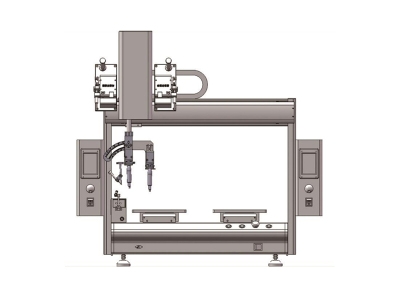

The average power of visual soldering machine equipment 300-350W, compared with wave soldering reflow, to a great extent, saving the cost of electricity in the factory, visual soldering system is the core element of visual soldering machine, the amount of tin per solder joint can be accurate to 0.1mm, and the solder joint is set to send how long the tin wire is sent long, there is no serious waste. With manual soldering and wave soldering and other equipment, saving the cost of tin line, automatic dispensing machine is widely used in semiconductor, electronic parts, LCD manufacturing and other fields.

The investment funds of the visual soldering machine equipment are used in the later formal volume, and the specific work efficiency of one of its problems can be quantified, which, to a certain extent, improves the efficiency of the entire social production management of the enterprise, and also reduces the impact of artificial environmental factors on the output and production.

Before using a welding machine, you should know the difference between a visual welding machine and a manual welding machine. The soldering machine manufacturer's visual soldering machine can only replace your hand, can not complete a complete set of welding tasks, visual soldering machine through the data on the microcomputer control solder. All the data is stored in the microcomputer controller, requiring the staff to output as early as possible. The visual welding machine automatically calls the stored data during the task execution, including the welding head preheating time, shaft movement interval, welding time, welding status, etc. It can be seen that in addition to some complex solder joints and machine reasons, to ensure the quality of solder joints is basically up and down or depends on people. How to improve the efficiency of visual welding machine welding wire?

1, the visual soldering machine needs to be designed and debug the machine in advance, so that in the welding process, it will not lead to bad soldering parts, or for the leakage of welding, the welding precision is high, the yield is high, and the efficiency of the visual soldering machine welding will naturally be improved.

Often check whether the soldering machine has loose screws, to avoid visual soldering machine failure in the welding process, in the welding process, but also to prevent the appearance of irregular.

3. It is necessary to adjust the machine according to the characteristics of the product. After the welding sample is in place, this setting will be retained, and the next time you encounter the same wire, you can directly call the file solder, which is very efficient.